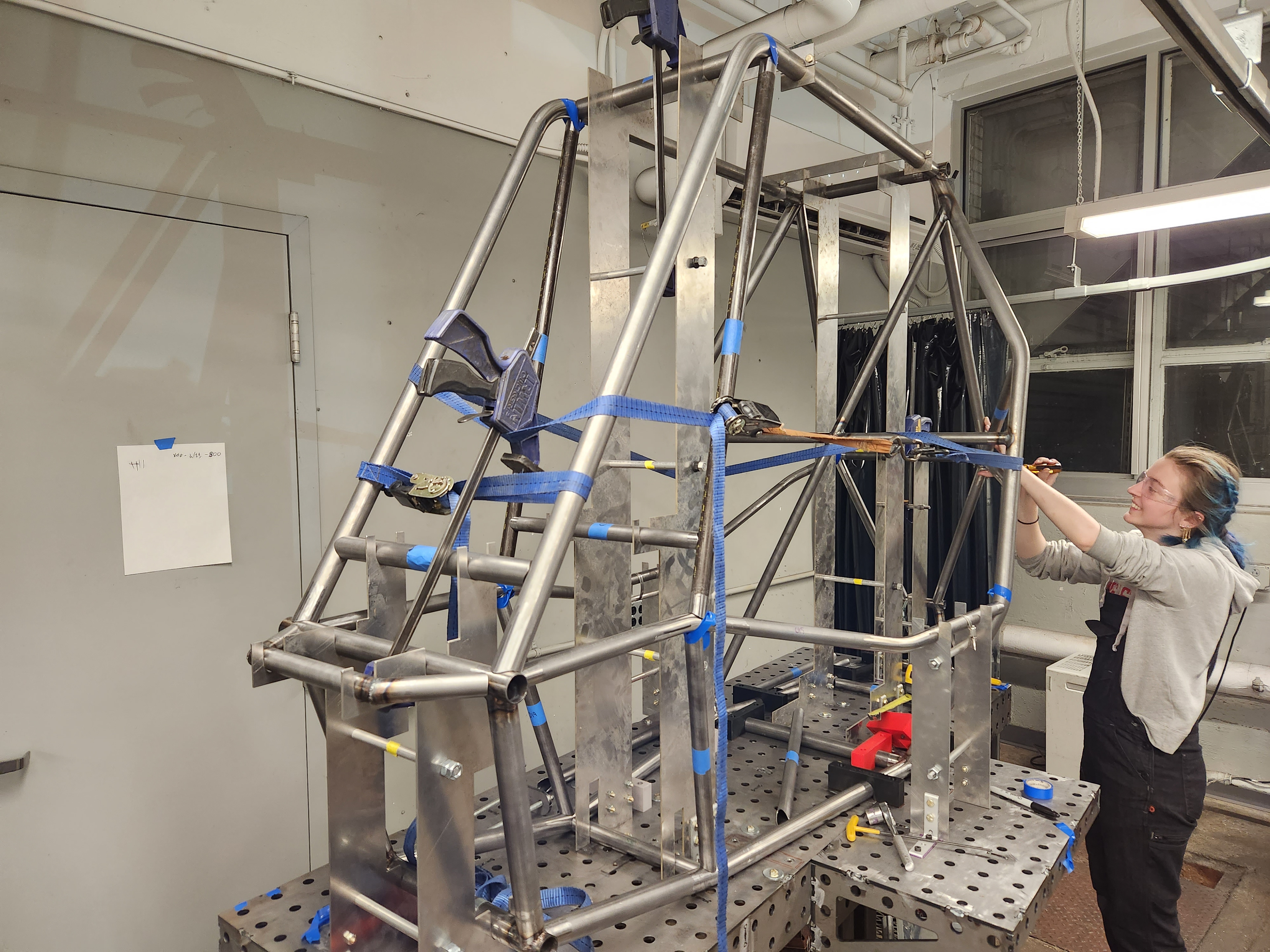

During my 5 years as a dedicated member of the Northeastern University Baja SAE team, I gained an immense of knowledge and practical experience as part of a small but knowledgeable group.

3 of my years on the team were spent as a sub team lead. First as the ergonomics lead where I focused on chassis geometry, driver safety, and keeping the driver comfortable and focused on racing. I then moved onto being the composites lead where I designed and manufactured composite seats and drivetrains to significantly lower the weight of the car.

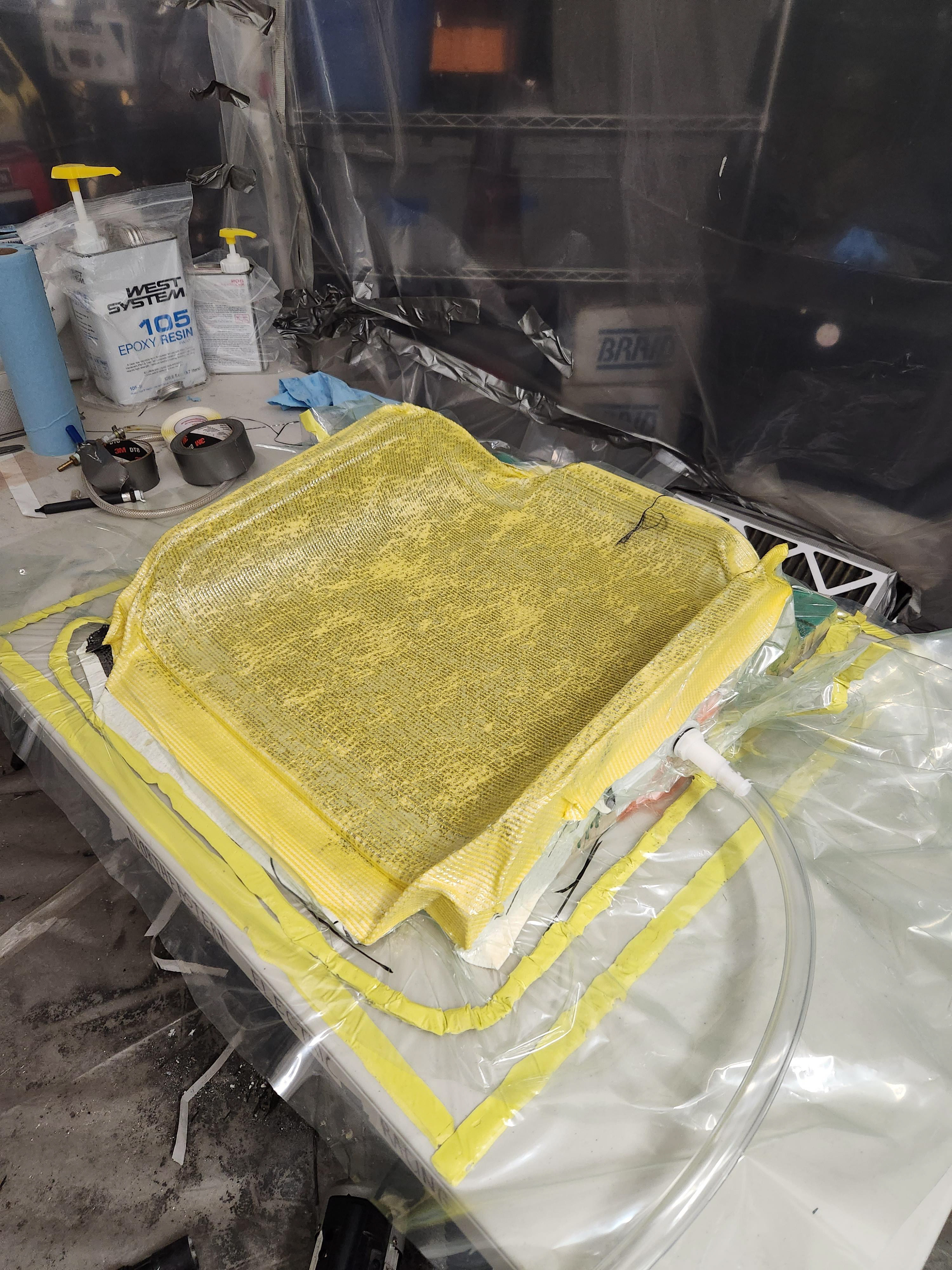

Once I became the ergonomics lead, I immediately looked in returning the ability to manufacture composite parts back to the team.

I did a lot of research on my own and scheduled various meeting with alumni that had graduated over 6 years ago. After about 2 months of hard work I finished assembling a small team and proposing a budget for initial tests.

Soon after the successful tests, I designed and manufactured an ASME compliant carbon fiber seat for competition use. This continued for my remaining years and resulted in 3 iterations of carbon fiber seats, each significantly better than the next and all designed and manufactured in-house.

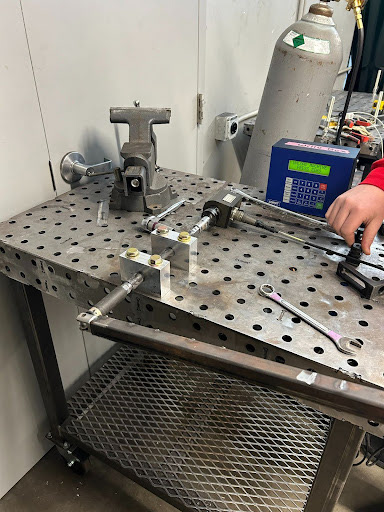

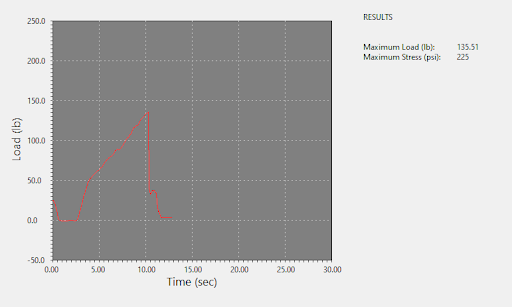

In addition, I proposed a carbon fiber driveshaft. After research and a proposal at the team's IDR (initial design review), I bonded a filament wound OTS shaft to custom splined, machined, and heat treated rod ends.

After testing, we saw that the driveshaft did not meet the minimum FOS we had set and reached out to alumni and racing companies to ask questions. After learning we had made a mistake during the prep stage, we created another driveshaft that passed our tests.

Steel Driveshaft: 5.13 lbs

Carbon Fiber Driveshaft: 2.018 lbs

The new driveshaft was only 39.3% the weight of the old driveshaft, an extreme reduction in reciprocating mass which significantly improved our acceleration time and deducing overall drivetrain resistance.

In addition, I led a variety of other projects during my time as the ergonomics lead. Steering wheel design and manufacturing, forged carbon testing, sheet metal design and manufacturing.